Properties

Whatever properties are required for your parts,

we have the solution.

Ability to weld : joining of two materials (two metals generally) by heating.

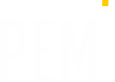

Ability to join two metals by a particular welding process involving the friction of a wire on a flat surface. Wire bonding is a microelectronic assembly technique for the interconnection between an electronic component and an electronic board (leadframe, PCB).

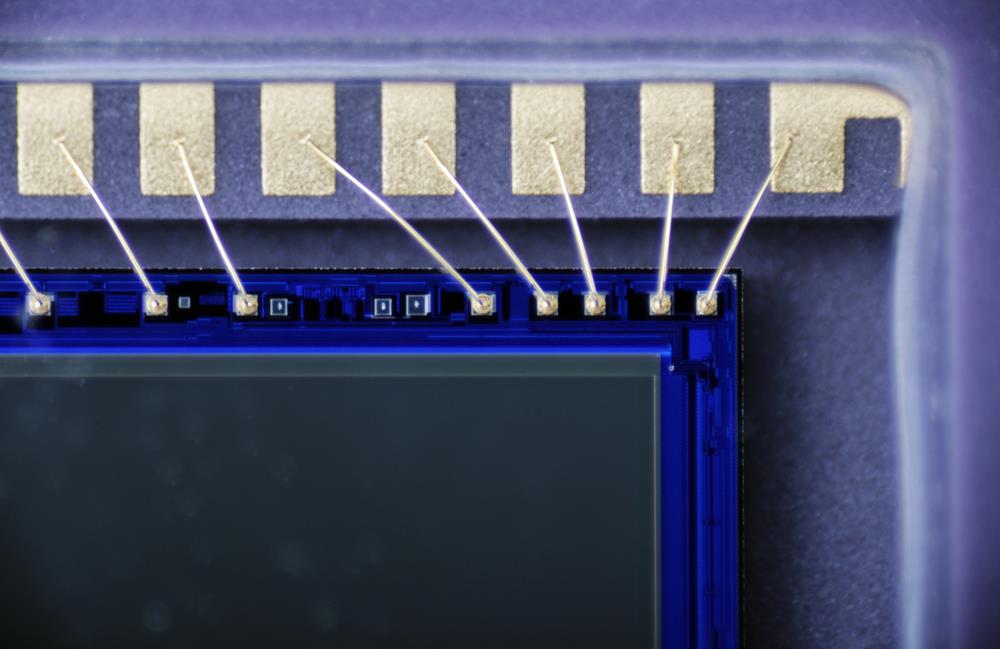

Ability to soldering : a method for joining two metals by melting a filler metal or an alloy (generally tin or a tin alloy).

Ability to join a die to a PCB or a leadframe by soldering or gluing (conductive adhesive).

Electrical resistance measured at the junction of two materials.

High electrical resistance characterized by a breakdown voltage (the minimum voltage that causes an insulator to become electrically conductive).

This characterizes the appearance of a surface in terms of color and shine.

Ability of a surface to be bonded to another surface using a glue, a resin…

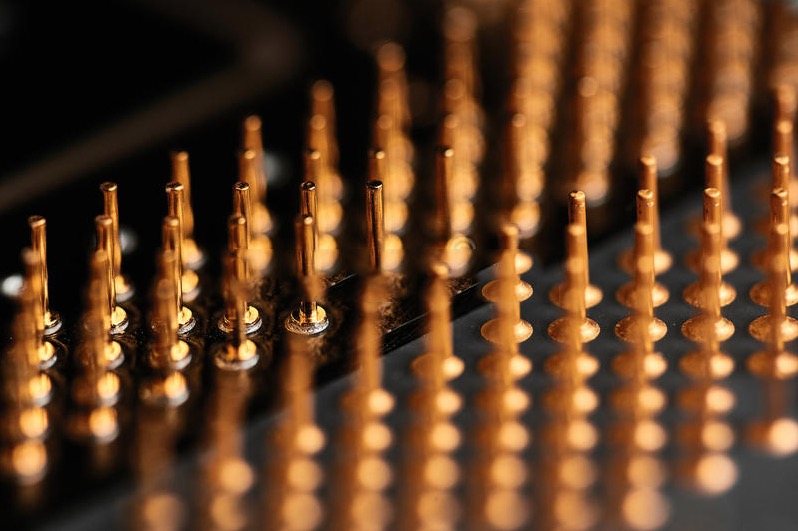

Treatment to protect a substrate from the corrosion.

Treatment to delay ageing of a surface (oxidation, diffusion…).

Terms used to characterize specific optical properties related to the absorption/reflection of an electromagnetic radiation.